The pharmaceutical industry poses specific hygiene-related demands on the manufacture of packaging.

- Constant monitory and strict quality control measures allow us to exceed all our customer’s expectations .

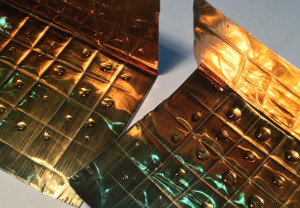

- The aluminum we use is of 99.7 % purity .

- The resistance of the external coat is regularly checked using the ” crush test”.

- Our tubes are tested to more rigorous standards and for more exacting tolerances than those prescribed by EN or DIN .

- The porosity of the internal coating is monitored using the ” conductivity leakage test ” several times a day .

- UMP uses class D HEPA Filters in its clear room production lines.

- The outside diameter of the tubes are monitored during the regular ” in-process inspections test ” several times a day .

- ump is ISO 9001 certified and being subject to recertification every three years , the consistency of our quality is guaranteed at all times .